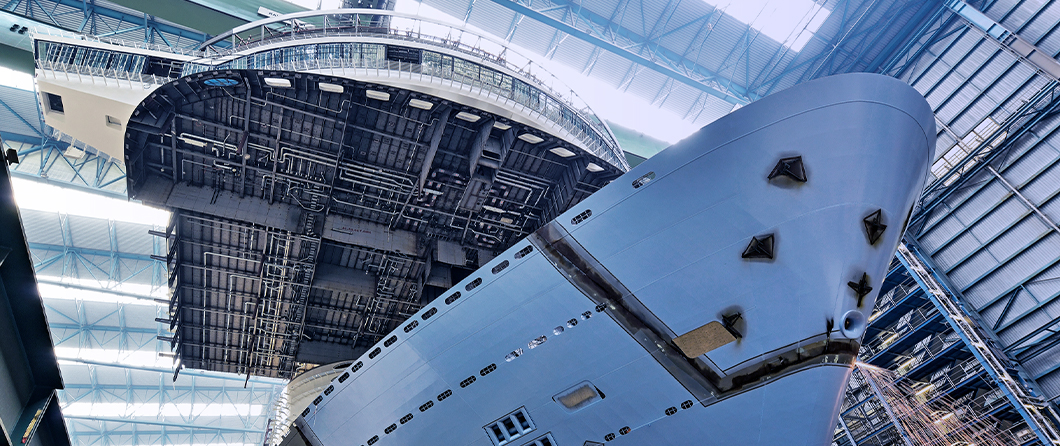

Just like Lego: turning small pieces into something big

Modern shipbuilding uses modular construction processes. Our engineers use computer programmes to break the ship down into small, Lego-like pieces. Each module is pre-assembled – including all the necessary fittings, such as cable shafts, air conditioning ducts and even balconies. The individual building blocks – up to 80 per ship – are only joined, welded together and wired at the dry docks right at the end. This means different groups of specialists can work simultaneously on one ship to drastically reduce the construction time.

Cutting-edge design software

A cruise ship is a floating metropolis, featuring everything you’d expect from an onshore city, such as power supplies, air conditioning systems, fresh and waste water technology, inventory management and waste disposal. Everything has to work smoothly behind the scenes. Shipbuilding is a modern industry that brings together a wide range of technology in a limited space. MEYER WERFT processes well over 15 million parts for each of its ocean liners. By way of comparison, around one million parts go into the construction of an Airbus A 380, and a car is made of approximately 10,000 components.

The development and construction of cruise ships is a highly complex and challenging operation. That’s why computer-aided technology is integrated at every stage, from planning to completion. How many kilometres of cables have to be laid on the ship and how much do they cost? How does the weight have to be distributed to ensure the ship remains stable in the wind and waves? When does each production stage have to begin to ensure the timely delivery to the shipping company? Which materials have to be used to ensure fire safety and soundproofing? All these questions – and many, many more – have to be considered by our designers. That’s why we first design and construct our ships using virtual 3D models and moving visualisations. Each new ship has to be recalculated to ensure a unique and tailored design.

The work at our shipyard reflects the principles of Industry 4.0 – all stages are planned, processed and controlled using digital and highly automated means. After all, every last cog has to fall into place to ensure the highest quality within the agreed budgets and deadlines.

Logistical achievements for the environment

Logistics is a crucial aspect of the shipbuilding industry. Over 15 million parts have to come together in the right place at the right time for the construction of our imposing ocean liners – and maximum attention has to be paid to environmental concerns. We use an innovative and automated transport management system to sustainably organise the material flows at our shipyard. This calculates the best transport routes for our low-emission, LPG-powered forklifts to reduce our carbon footprint.

And we want to keep improving. That’s why MEYER WERFT has invested around 40 million euros in a new logistics centre. The fully automated flow of goods, which offers space for 25,000 units, ensures even greater efficiency. Our suppliers can also relocate to the new logistics centre to cut our transport routes even further. Green logistics – made by MEYER.